- Applications

-

Products

-

Liquid Handling

- firefly Accelerate genomic research with innovative all-in-one, compact liquid handling

- mosquito Nanolitre liquid handling technology performs ‘traditional’ tasks at a fraction of the volume, and higher speeds

- dragonfly Delivers accurate and repeatable nanolitre to milliliter dispensing

- apricot Automated liquid handling instrumentation for convenient general use across your entire team

- Sample Preparation

-

Sample Management

- comPOUND A scalable, reliable, and secure compound management solution

- BioMicroLab Easy-to-use sample management automation instruments

- arktic Robust biospecimen storage and management down to -80°C

- lab2lab Novel sample and data transfer network system

- comPACT Reliable and efficient -20°C storage and retrieval has never been more accessible

-

Liquid Handling

-

About

- Company With a focus on liquid handling, sample preparation and sample management, our expert teams create state-of-the-art solutions that scientists and researchers can trust Culture We have one overarching mission: to work together to accelerate life science research. Through our innovative solutions and state-of-the-art tools, we believe we can make a real difference to human health Partners Collaboration is key in our mission to make a real difference to human health. Partnering with application leaders globally, we co-create to solve new challenges across the life sciences. Innovation From the initial prototype through to manufacturing, installation and beyond, we bring a problem-solving mindset and technical expertise to drive innovation

-

Executive Leadership

Through strategic guidance, visionary thinking, and a relentless pursuit of excellence, our senior executives steer SPT Labtech towards achieving its mission of making a real difference to human health through solving advanced laboratory challenges.

Learn more

Through strategic guidance, visionary thinking, and a relentless pursuit of excellence, our senior executives steer SPT Labtech towards achieving its mission of making a real difference to human health through solving advanced laboratory challenges.

Learn more

-

View all

Board of Directors

Board of Directors

Our Board of Directors are committed to driving the long-term success and sustainability of SPT Labtech, providing expert guidance and oversight to execute the company’s ambitious commercial strategy.

Learn more

Our Board of Directors are committed to driving the long-term success and sustainability of SPT Labtech, providing expert guidance and oversight to execute the company’s ambitious commercial strategy.

Learn more

-

Knowledge Base

- Resources Our wide range of insightful resources include videos, whitepapers, eBooks, application notes and more Events & Webinars Meet the SPT team at events all over the globe and virtually via our webinars Podcast We chat with innovators and leaders from across the community to gain their unique insights. News Latest news from SPT Labtech globally Blog Our latest blog posts feature trends in research, innovative techniques and new technology

-

26 March, 2025

SPT Labtech and Biortus Launch Joint Laboratory of Structural Biology in China

Continue reading

SPT Labtech and Biortus Launch Joint Laboratory of Structural Biology in China

Continue reading

-

17 December, 2024

Connect with SPT Labtech at SLAS 2025

Continue reading

Connect with SPT Labtech at SLAS 2025

Continue reading

-

16 December, 2024

SPT Labtech 2024 Year in Review

Continue reading

SPT Labtech 2024 Year in Review

Continue reading

10

- Careers

.jpg)

Rapid access storage and streamlined sample management workflows

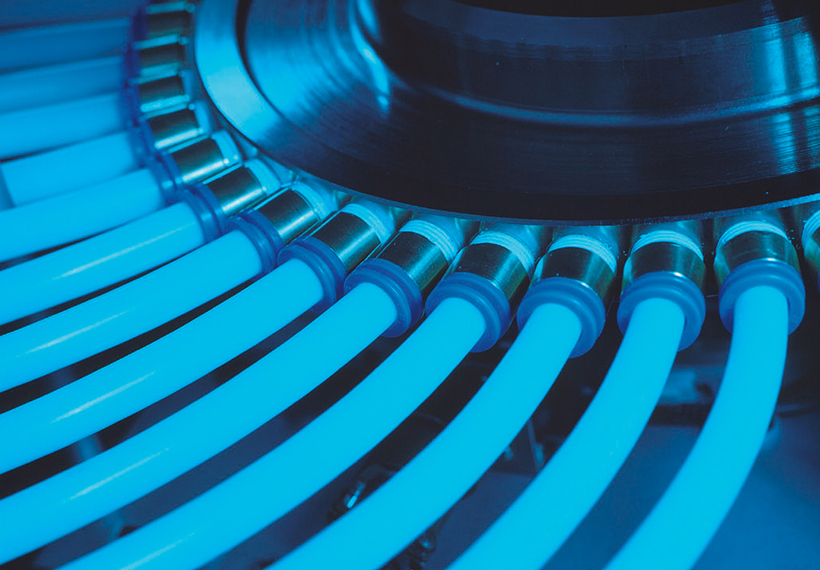

comPOUND provides secure storage for 2D barcoded tubes at -20°C, +4°C, and ambient temperature. Its innovative carousel system delivers high density storage within a small footprint, compact unit and allows for rapid retrieval through the convenient vending machine style design. The modular approach allows facilities to scale flexibly, connecting individual units across locations using innovative and reliable pneumatic transport technology.

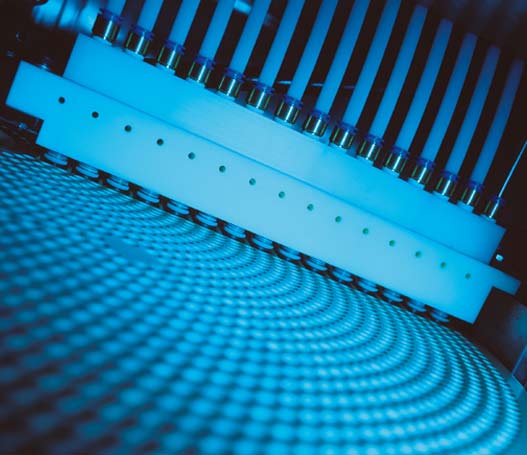

Vending machine style design for convenient sample retrieval

The user-friendly and convenient vending machine style design enables easy and secure access to samples. The ability to only retrieve requested microvials avoids unnecessary freeze/thaw cycles and maintains full sample integrity.

Innovative carousel system for high density, low footprint storage

The innovative carousel system optimizes storage capacity, allowing facilities to capitalize on available space and proactively control overheads by maintaining low running costs.

Novel pneumatic technology assures reliability and streamlines workflows

The innovative pneumatic technology minimizes the use of electrical and mechanical components in the cold zone to ensure exceptional reliability. Harnessing pneumatic power enables fast cherry picking of samples and seamless onward transportation to remote locations.

Modular structure enables scalability and futureproofing

Self-contained modules can be flexibly located and linked to increase sample throughput and enable growing compound libraries to scale efficiently.

Fast pick rate boosts productivity

Automated cherry picking saves facilities hours of highly qualified researcher and technician time in comparison to manual searching, dramatically increasing productivity. With a single comPOUND typically replacing two to three manual freezers, facilities can improve cost-efficiency and benefit from significant workflow improvements.

User Case Study

Unique pneumatic technology underpins our portfolio of automated sample storage and retrieval solutions, ranging from ambient temperature to -80°C. By automating routine manual tasks, these systems enhance efficiency and free up scientist time, while also instilling confidence in research and data outcomes through comprehensive sample tracking.

In this user case study, a growing library of 25,000 oligo samples was transformed by implementation of comPOUND® for automatic storage and retrieval at -20°C. This system was selected for its proven and robust technology, scalable modular design, and compatibility with the lab’s existing work cell.

The result: completely touch-free batch collection and daily sample retrieval processes. This integration saved hours of manual labor each day, enabling the team to meet the increasing business demands of supporting drug discovery labs.

comPOUND Citations

Technical Specification

Scroll to view more information

| Storage conditions | Dry air or nitrogen, hermetically sealed with user-defined temperature at +4°C, ambient and -20°C store | Approximate dimensions (W x D x H) | 1.2m x 1.65m x 2.4m 48in x 65in x 93in |

| Capacity and throughput | Storage of 100,000 x 1.4 mL vials, 200,000 x 0.5 mL vials and throughput of 600 vials/hour | User interface | Simple UI at local console |

| Input and output format | 96-position SBS racks with 2D barcoded tubes | Power | Europe: 230V 50Hz. US: 208V - 240V Two phase @ 60 HzMax power consumption during normal use is 1.8 kW, average 1.25 kW |

Expand the performance of your compound

Accessories

We have two core accessories available to expand the performance of comPOUND. comSTACKER enables walk-away operation and the Connect XC system allows for unattended processing of orders consisting of up to 150 racks of tubes.

Explore comPOUND accessories

What our customers

say about comPOUND

Modular equipment that can be scaled up to increase capacity with a minimum of effort

"This equipment is very effective for compound management. The original purchase of two modules was expanded to 3 then 4 in a seamless manner. A D2 variant of the store was added some time later for a different sample set. The modularity and scalability of the kit was necessary for a small-medium compound management facility like ours."

David Camp

Griffith University

Quick, reliable and accurate! compound gives us scope to progress.

"comPOUND for us invaluable, as we demand a quick reliable service. we get walk away time added by having compound either store or pick vials. These are all ready for the end user, so are kept at the perfect storage temperature. we also get 100% accuracy, which cannot get replicated with human use."

Mr Glen

Abcam PLC

These particular units were chosen for their compact size, large storage capacity, reliability and sample management capabilities. We also chose SPT Labtech because of its professionalism and customer service. We’ve installed five comPOUND units and moved them around on site. For all the comPOUND installations the TTP Labtech engineer had each unit uncrated, built and running seamlessly within a day. Before the introduction of Australian distributors, SPT Labtech provided an excellent support service for us even though they are located several thousand miles away. All these factors were crucial to Compounds Australia’s decision to select SPT Labtech and comPOUND in order to supply high quality samples efficiently and at low cost to our customer network

Moana Simpson

Griffith University

Very intuitive equipment. Installation was extremely quick. We experience small issues every so often that are quickly fixed by SPT.

Ludovic Otterbein

Lundbeck

As a team of exceptionally skilled scientists, engineers and business innovators, we have one mission: to work together to accelerate life science research.

.png)