- Applications

-

Products

-

Liquid Handling

- firefly Accelerate genomic research with innovative all-in-one, compact liquid handling

- mosquito Nanolitre liquid handling technology performs ‘traditional’ tasks at a fraction of the volume, and higher speeds

- dragonfly Delivers accurate and repeatable nanolitre to milliliter dispensing

- apricot Automated liquid handling instrumentation for convenient general use across your entire team

- Sample Preparation

-

Sample Management

- comPOUND A scalable, reliable, and secure compound management solution

- BioMicroLab Easy-to-use sample management automation instruments

- arktic Robust biospecimen storage and management down to -80°C

- lab2lab Novel sample and data transfer network system

- comPACT Reliable and efficient -20°C storage and retrieval has never been more accessible

-

Liquid Handling

-

About

- Company With a focus on liquid handling, sample preparation and sample management, our expert teams create state-of-the-art solutions that scientists and researchers can trust Culture We have one overarching mission: to work together to accelerate life science research. Through our innovative solutions and state-of-the-art tools, we believe we can make a real difference to human health Partners Collaboration is key in our mission to make a real difference to human health. Partnering with application leaders globally, we co-create to solve new challenges across the life sciences. Innovation From the initial prototype through to manufacturing, installation and beyond, we bring a problem-solving mindset and technical expertise to drive innovation

-

Executive Leadership

Through strategic guidance, visionary thinking, and a relentless pursuit of excellence, our senior executives steer SPT Labtech towards achieving its mission of making a real difference to human health through solving advanced laboratory challenges.

Learn more

Through strategic guidance, visionary thinking, and a relentless pursuit of excellence, our senior executives steer SPT Labtech towards achieving its mission of making a real difference to human health through solving advanced laboratory challenges.

Learn more

-

View all

Board of Directors

Board of Directors

Our Board of Directors are committed to driving the long-term success and sustainability of SPT Labtech, providing expert guidance and oversight to execute the company’s ambitious commercial strategy.

Learn more

Our Board of Directors are committed to driving the long-term success and sustainability of SPT Labtech, providing expert guidance and oversight to execute the company’s ambitious commercial strategy.

Learn more

-

Knowledge Base

- Resources Our wide range of insightful resources include videos, whitepapers, eBooks, application notes and more Events & Webinars Meet the SPT team at events all over the globe and virtually via our webinars Podcast We chat with innovators and leaders from across the community to gain their unique insights. News Latest news from SPT Labtech globally Blog Our latest blog posts feature trends in research, innovative techniques and new technology

-

26 March, 2025

SPT Labtech and Biortus Launch Joint Laboratory of Structural Biology in China

Continue reading

SPT Labtech and Biortus Launch Joint Laboratory of Structural Biology in China

Continue reading

-

17 December, 2024

Connect with SPT Labtech at SLAS 2025

Continue reading

Connect with SPT Labtech at SLAS 2025

Continue reading

-

16 December, 2024

SPT Labtech 2024 Year in Review

Continue reading

SPT Labtech 2024 Year in Review

Continue reading

10

- Careers

- Home

- Products

- BioMicroLab

- BioMicroLab XL100

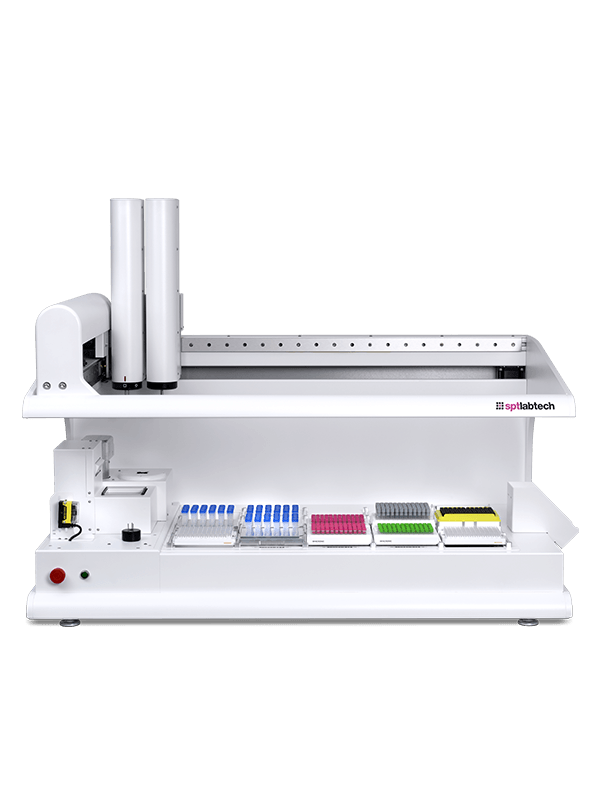

BioMicroLab XL100

Flexible and modular benchtop tube handling for diverse sample management workflows.

Simplify complex tube and vial handling tasks

The BioMicroLab XL100 simplifies complex tube and vial handling tasks including volume detection of low sample volumes, liquid transfer, labeling, capping, de-capping, and re-arraying. Compatible with tubes and vials up to 125 mm in height and designed with an interchangeable pick-head, laboratories benefit from the flexibility of using the same instrument for different tubes and vials.

Multiple capabilities within a single instrument to streamline workflows

The XL100 brings together scanning, decoding, re-array, labelling, weighing, capping/decapping, and liquid transfer capabilities within a single user-friendly instrument. Its modular design offers researchers and operators the flexibility to use it for individual tasks, or to accomplish multiple tasks as part of a single workflow.

Generous 20 rack capacity deck maximizes efficiency

The generous capacity enables researchers to pre-load 20 racks, reservoir plates or pipette tip boxes, removing tasks from the critical path and increasing research productivity. For a 30 rack capacity deck, see the XL200.

Re-array, reformatting, and cherry-picking designed for compatibility

The instrument’s pick fingers adjust to a wide variety of tubes and vials, and the XL100 is compatible with ANSI/SLAS format tube racks, including honeycomb format racks and PCR plates.

Efficient sample identification and tracking

The XL100 seamlessly integrates 2D and 1D barcode decoding with other tube handling operations for easier sample identification and tracking.

Simplify label printing and application with integrated labeling module

Our LabelPro module applies high-resolution labels printed with 1D & 2D barcodes, symbols and human readable text to tubes and vials - reducing the burden of manual labeling tasks and eliminating bottlenecks.

Efficient collection of sample weight data

To verify volume upon receipt of samples, or before/after liquid transfer operations, the XL100 integrates precision balances to automate the collection of sample weight data.

Robust and reliable day-to-day operations

The XL100 has a proven track record of reliability, ensuring maximum uptime for day-to-day automated sample management operations and safeguarding research productivity.

Benchtop and high performance tube and vial handling

XL Series Tube and Vial Handlers streamline liquid transfer, volume detection, sample identification/verification, labeling, capping/de-capping tasks to eliminate bottlenecks and transform tube handling workflows.

- Software

- Temperature management

- Compatible labware

- Enclosures

- Label printing and application

- Sample identification and tracking

- Volume detection

- Liquid Transfer

User-friendly Windows based software is included with all XL Series instruments to manage sample processing modes and robotic operations. BioMicroLab offers software developer toolkits for your instrument and workflow integration projects.

XL Work List Manager Software

Included with all XL Series instruments, the XL Work List Manager Software offers user-friendly management of vial pick and place operations. It provides multiple tube processing modes for common tube handling applications to meet varied workflow needs and allows researchers flexible control to increase your throughput. Output files can be easily configured to meet LIMS system requirements. Easily managed by multiple users, our full featured tube processing software provides walk away operation to meet throughput requirements even for demanding environments with advanced system error handling options. Software features include:

- User-friendly point-and-click Graphical User Interface

- Data collection and worklist based processing modes

- Functionality carefully guides the user through the tube rack loading and unloading process

- Interactive interface provides feedback while processing tubes

- Dynamically processes extended work lists handling more racks than the XL Series platform capacity

- Integrates with hand-held barcode scanners for rack identification

- LIMS integration ready output files in .csv file format

- Tracks and logs all system activity

- Provides robust error-handling options for unattended tube processing

- SDK & ActiveX toolkits available

Cost effective solutions to temperature management are available depending on the application. Options include models built for cool room environments, or a system integrated directly on the XL Series instrument platform, such as Solid State Cooling system or Mécour Thermal block, to maintain steady sample temperatures.

The XL100 is compatible with commonly used microtubes, cryovials and vials up to 125 mm in height!

- 96, 48, 24, 12, 6 format SBS tube racks

- 0.2 mL to 15 mL+ tubes and vials

- 2 mL cryovials

- 4 mL, 6 mL, 8 mL glass vials

- conical tubes (i.e. 15mL Falcon tubes)

- Vacutainers

Please inquire if you do not see your labware listed, as it still may be compatible!

When operator safety is a concern, the XL100 can be enclosed so that the instrument automatically shuts off when the door is opened. Clear, acrylic walls allow maximum light and visibility into the instrument to support comfortable user conditions. Enclosures are now available with HEPA filtration.

The LabelPro module prints and applies high-resolution 1D & 2D barcodes as well as human readable text and symbols. User-friendly software allows operators to generate unique or identical labels using a variety of label materials and sizes.

Download XL100 LabelPro FlyerThe XL100 seamlessly integrates 2D data matrix barcode decoding with other tube handling operations, decoding up to 500 tubes per hour. BioMicroLab’s software captures and reports each tube’s 2D barcode, tube location, weight, volume and more to LIMS systems.

The instrument integrates either a precision 4-place or 5-place automated balance to automate the collection of sample weight data and easily verify volume upon receipt of samples, or before/after liquid transfer operations.

We offer automated liquid handling with the Tecan ADP pipetting module, configured on your XL Series Tube Handler via a separate Z-axis to allow seamless integration with other tube handling tasks. The Cavro ADP single channel pipette uses air displacement technology or conductive tips to aspirate or dispense fluids to and from any tube, vial or rack position!

Technical Specification

Scroll to view more information

| Dimensions (W x D x H) | XL100: 45in x 28in x 35in (115cm x 72cm x 89cm) XL100 with Labeling: 45in x 36.5in x 35in (115cm x 93cm x 89cm) XL100 with Labeling and Cap Feeder for Glass Vials: 52in x 36.5in x 35in (132cm x 93cm x 89cm) XL100 with Cap Feeder for Sarstedt Tubes: 70in x 28in x 35in (177cm x 72cm x 89cm) |

Electrical | 100-240VAC 60Hz |

| Weight | XL100: Starts at 100 lbs (45.5 kg) XL100 with Labeling: Starts at 122.5 lbs (55.6 kg) Actual weight depends on the configuration options |

Operating Environment | -10°C to 40°C, 10-90% RH Sample temperature may be ambient or frozen. Temperature Integrity Systems available to maintain steady sample temperature between -85°C to 80°C |

| System Requirements | Operating System: Windows 11, 10; 8GB RAM Recommended USB Ports: Two Serial Ports: One |

Throughput (Operational Module - Tubes/Hour) | Re-array only: 500 Re-array and 1D or 2D Decode: 300 Re-array, 2D Decode and Weigh: 170 Re-array and Weigh: 170 Decap / Recap: 160 Label: 150 |