The system configuration is via the Config.xml file which is held in the Config sub-folder. As with lab2lab this should only be edited by, or following the instructions of, SPT Labtech staff.

You can adjust the runtime system settings via the building2building UI.

- Use the On/Off button at the top left to shutdown building2building. The button symbol is gray when shutdown.

- Click the settings button (with the gear symbol) at the bottom left.

The parameters that are visible in the Settings window vary depending on how the system has been configured. However, there are four settings which are always available.

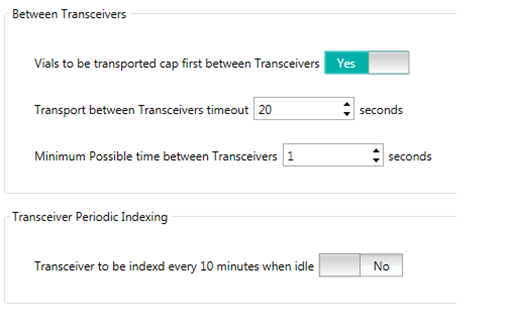

- Vials are generally transferred cap first between the Transceivers as this way they form a better vacuum seal when they arrive. Altering this setting is now deprecated.

- The Transport between Transceivers timeout is used for transport error detection, when a vial takes longer than anticipated or does not arrive at all.

- The Minimum Possible time between Transceivers is also used for error detection. Because the vials are being transferred over a long distance it would be an indication of a fault if a vial appeared to arrive at the receiving Transceiver too quickly. If this happens, the problem must be investigated.

- The last of the settings is the option to automatically index each Transceiver once (i.e. 90°) every ten minutes. This feature was included to improve reliability especially if there may be long periods of inaction.

In addition to these settings there are email Settings like those in the lab2lab Director. These enable building2building to send emails reporting errors and to generate daily summary emails (at midnight on active days). The daily summaries specify how many transfers occurred (total and, if the system is bi-directional, the number in each direction) as well as the times for the fastest and slowest transfers and the average and median values.